Epoxy/Polyester Hybrid Powder Coating Epoxy/Polyester Powder Coating

Epoxy/Polyester Hybrid Powder Coatings has combined properties of both epoxy and polyester, providing smooth and glossy coating with good bond ability and mechanical performance, excellent chemistry and corrosion resistance, better heat and light resistance

It is ideal coating and decoration of indoor metal (steel or aluminum) items such as:

1. Automotive accessories and underbody,

2. Electrical appliances,

3. Exercise equipment,

4. PCM steel plate

5. Displace racks,

6. light fixture

7. Metal furniture,

8. Computer bodies,

9. Refrigerators …

Finishing:

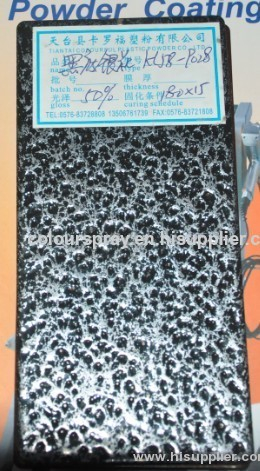

Smooth and special finish (texture, wrinkle, hammer etc) for all kinds of gloss are provided.

To ensure the applied powder coating will meet the specified performance requirements, there are on-site tests to be performed as:

Solvent cure test - Usually straight MEK or a less aggressive solvent is applied to the powder coated part and resistance to the solvent is used to evaluate the degree of cure.

Adhesion test - Cross Hatch tape pull test to evaluate the powder coating adhesion to the substrate.

Thickness - Testing instruments to accurately measure dry film builds. This is essential to ensure proper film builds are being applied.

Permeability - Usually for exterior applications, finished sample is placed in a pressure cooker with water, testf for adhesion.

Impact test - Evaluates powder adhesion and flexibility.

Hardness - Pencil hardness test evaluates powder hardness and cure.

Colour and gloss - Matched to coating supplier¡¦s standard panels.

Visual finish appearance - inspection of colour, gloss, flow, edge, coverage, texture etc. to powder coating suppliers standard.